A non-pressurized external reservoir system acts as a protective buffer between the product and the atmosphere. Minimum Siphoning Seal Leg Height - posted in Industrial Professionals.

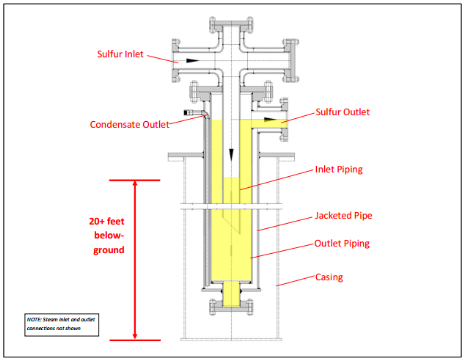

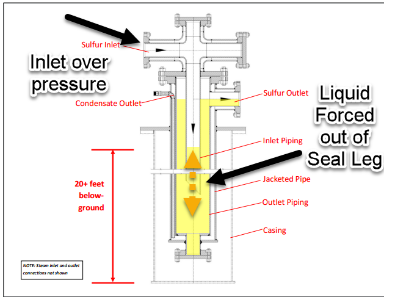

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Savings water consumption per seal per minute x number of seals x 60 x 24 x operation time in days every year x seal water price in dollars x reduction in water use1000.

. The liquid in the tailpipe is known the height should be adjusted accordingly. However it does identify concerns that are associat-ed with seal welding and the galvanizing practice. The mixed liquids enter a separator drum.

Buffer fluid is circulated between the inner and outer seal chamber. Factors which influence the solids flow rate through the loop seal include loop seal air velocity. The leg assembly should be designed for a straight vertical run or one with no more than a 45-degree turn.

The condensate form in these three horizontal condensers and drained directly to the storage tank. The seal leg is designed to match the tank blanket design pressure. A seal leg used in a piping system is a vent pipe that functions as a wayto control the fluid Continue Reading Skip to content 1 713 731-0030 Toll Free.

How Customized Seal Support Systems Work. Heres an example for a typical mill. As previously discussed mud-leg hydrostatic pressure must exceed vent-line friction pressure to prevent a separator blow through condition.

I think you will find some useful information on seal legs there. 8 This minimum condition mayor may not occur depending on the well location. The standard covers causes of overpressure and vacuum including additional scenarios to be considered for refrigerated tanks Table 2 2.

Finally rigid stainless steel hose clamps fit the scales together. 10 of the mechanical seal Shaftshaft sleeve diameters are always three-digit numbers beneath the stationary seat for types U and B Seal face Stationary seat Secondary seals Spring Other metal parts except seal cover and shaft sleeve Direction of rotation of the mechanical seal Type N and K Type C is also the spring winding direction R. HOTWELL DESIGN The designer must carefully consider open hotwell design in a process Figure 3.

This edition of Design File is not intended to be a treatise on galvanizing and preferred details for corrosion resist-ance. Note that the causes of vacuum are often the inverse of analogous causes. I like to design the down leg for self.

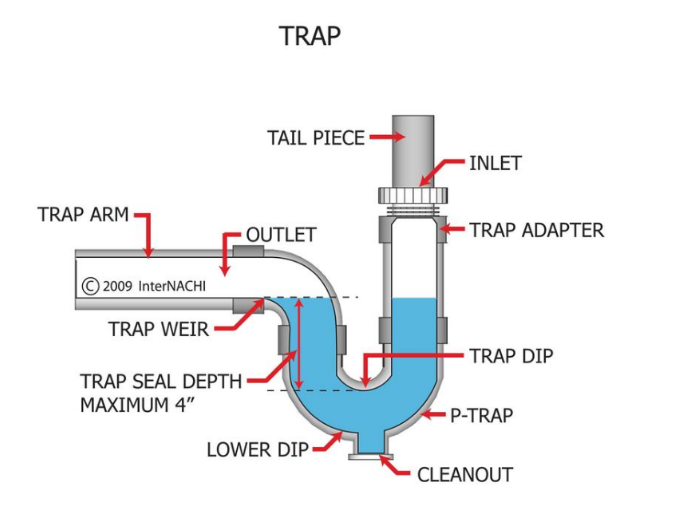

DESIGN FEATURES Many variations of seal drum are available to suit requirements but all serve the same basic function. 90-degree turns are not acceptable. The disposal location is carefully selected in the event that the liquid seal is lost and personnel exposure may happen because of nitrogen blowing through the seal leg.

Multiple seal arrangements are used to isolate toxic gases and fluids that can change state when exposed to the atmosphere. The underflow line has a seal leg inverted-U outside the vessel. Venting minimizes that concern.

The seal leg has to be set up to prevent the siphoning of liquid from the seal loop. From that drum the heavy separated liquid leaves through an underflow line and the light separated liquid through an overflow line. Dear SirMadam Sorry to bother you this trivial.

In all cases the inlet tube forms the dip leg and the gas having displaced all liquid from the tube bubbles through the liquid to. The system is effectively sealed by submerging the leg pipe 6-8 inches below the hotwell liquid level so atmospheric airvent gases cant be pulled back into the piping. API Standard 2000 defines the venting requirements for atmospheric and low-pressure storage tanks for both overpressure and vacuum.

The operation of a loop seal in a circulating fluidized bed is studied on the basis of pressure balance of the circulation loop. Liquid-acid vaporizes and expands when the part is dipped into the hot zinc. Operation time in days every year.

Since the condensate drains by gravity the barometric leg must be high enough to make sure the condensate does not enter the condenser and flood the lower tubes. Click Image To Enlarge Figure 1 -- Liquid seal loop system. From sulfur processing equipment to jacketed piping specialty engineering and ControTrace and ControHeat tracing and heating systems CSI provides the products you need to optimize your capital and operational costs.

The contact surfaces of both scales fit together with tongue and groove connections creating a very efficient seal between the two scales. 4 liters per minute. Provides trusted thermal process solutions to plants around the world.

How can I determine the minimum height of the seal leg. Minimum mud-leg hydrostatic pressure would occur if an oilgas kick was taken and the mud leg was filled with 026 psift oil. Alarm is also provided to alert the operator in case of loss of liquid seal.

The basic design principle involved with a liquid seal is to prevent light hydrocarbons from entering downstream processes by managing a liquid interface level while draining. The leg seal consists of two scales manufactured from flexible material which cover the leg on the top and the sleeve on the bottom. During normal operation liquid sulfur flows into the seal leg via a rundown.

If the tubes flood they will not be able to transfer heat effectively. The sharp-crested theory of free surface flow is applied to analyze the solids flow rate through a loop seal. Water consumption per seal.

Good practice recom-mends that the hotwell area be equal to 15 times the tailpipe volume measured from the bot-tom of the tailpipe to the point of overflow not less. Similar to a P-trap liquid sulfur in the bottom of the seal leg establishes a vapor seal preventing H2S and SO2 vapor from passing into the. Seal legs katmar Chemical 25 May 10 0100.

Technical Papers and Case Studies. Once inside the device sulfur flows downward through the inlet piping to the bottom of the leg and then upward through the annular outlet piping to the sulfur outlet. Improper barometric leg design will reduce the performance of the condenser.

The system is effectively sealed by submerging the leg pipe 6-8 inches below the hotwell liquid level so atmospheric airvent gases cant be pulled back into the piping.

Fluidmaster Better Than Wax Universal Wax Free Toilet Seal 7530p24 Universal Design Seal Design Toilet Repair

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Liquid Seals On Flare Vent Stack Enggcyclopedia

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Flex Seal Liquid Rubber Sealant Liquid Rubber Sealant

0 comments

Post a Comment